Automation Development provides equipment solutions for automated and semi-automated assembly and test of your product.

Automated Equipment may integrate vision sensors, robotics, motion control, material handlers and different assembly methodologies.

Our engineering expertise can deliver the best automation solution for your application. We can create high-speed, high-precision systems to meet the most demanding of challenges.

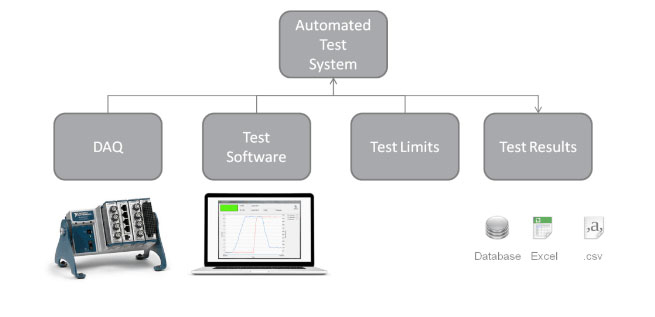

Silicon provides services for test & measurement Systems to support following industries