Silicon delivers best-in-class Product Development design services across key industries.

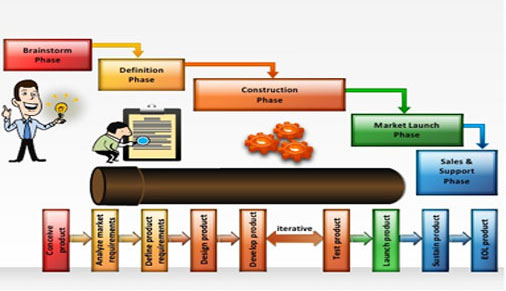

Our global Development Engineering teams use a phased approach to generate concepts,

specifications, detailed designs and prototypes to develop a fully realized product,

ready for manufacture. By utilizing our phased development approach, we are able to

provide reduced time-to-market and time-to-revenue, and can quickly adapt to the ever changing market demands.

At Silicon, New Product Development (NPD) activity is very important, as we understand that our success is dependent on your success. Our goal is to ensure a smooth transition

of your prototypes to the production environment, in any part of the world, with no impact to your schedule.

Depending on how early in a product’s life cycle our customer engages our services, initial entry points for NPD activity will vary. Strategies for materials, manufacturing, and testing can be formulated early in the concept phase of a product development.

Early collaboration of technical teams on the electrical and mechanical design of a product can take the bumps out of the road to meeting cost, quality and cycle time requirements once your product enters volume production.

Designing & Development of new products or services to benefit customers

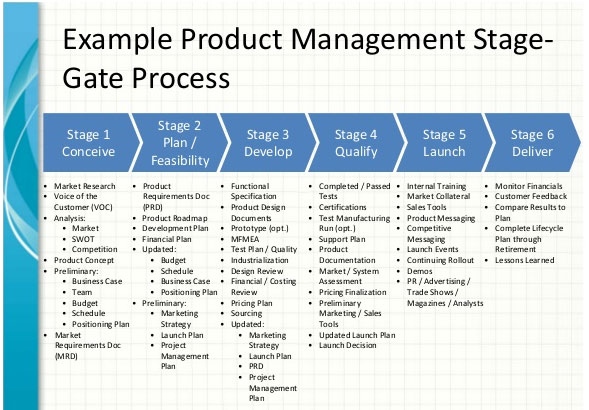

Silicon phase gate development process is part of a certified management system.

As a customer-driven organization, we can adapt this process to meet your requirements, or we can change our methodology to work completely within the bounds of your organization’s process.

Silicon brings unmatched ability to convert your basic ideas and user needs into workable concepts and prototypes.

With cross functional teams and highly competent engineers with experience in a variety of niches including, industrial design,

product development, material science, manufacturing, and engineering, we can deliver concept designs, feasibility studies and more!

- CAD (Computer aided design)

Silicon brings unmatched ability to convert your basic ideas and user needs into workable concepts and prototypes.

With cross functional teams and highly competent engineers with experience in a variety of niches including, industrial design,

product development, material science, manufacturing, and engineering, we can deliver concept designs, feasibility studies and more!

Products work best when they are engineered to precision and manufactured using the most suitable of materials, which is

again a balance of cost, performance, and intent. Our material science experts specializing in polymer science bring in-depth know how

in material selection. Be it cost savings or product improvement: we are ever open to sharing our expertise and knowledge.

Any product needs to be tried, tested, and perfected to ensure a smooth launch and rapid consumer acceptance. To this end, we

undertake functional prototype development for companies. Whether it is for evaluating new concept or design changes or

improvisations based on innovations, for functional testing or feasibility study, we develop functional prototype using a

variety of prototyping techniques.

- Detail Design and Engineering

Research, analysis, feasibility studies and so on culminate in ultimately in design detail and engineering, to develop the best product.

Our collaborative teams deliver bespoken solutions that are high in value and Silicon undertakes tasks-based engineering projects,

or even complete ownership, in executing designs and developing the product from the concept to finish.

Initial reliability activities involve computational analysis in the design and concept phases. Engineers are looking to ensure the design will meet the environmental and application requirements for the product. Typical computational analyses include Mean Time Between Failure (MTBF), Failure Mode Effects Analysis (FMEA), Tolerance Analysis, and others.

Once the design team has completed the various analyses and the design has been detailed and built, prototypes and production units undergo actual testing to ensure the product meets requirements.

Specialized testing is performed to assure that system design requirements are met. Silicon engineers support and work with the Test Development and Product Development project teams.

- EMI/EMC

- Vibration

- Shock

- Humidity

- Temperature

- HALT (Highly Accelerated Life Testing)

- HASS (Highly Accelerated Stress Screening)

- Altitude

- Explosion

- Corrosive Atmosphere

- Ongoing Reliability Testing and Monitoring

- Risk Analyses

Silicon’s s design teams integrate with yours to provide the design expertise you need, and to help ensure the success of your

entire project.Our development processes are structured to make your product concept into a production solution.

This involves examining customer resource availability and technology requirements, and using experienced Silicon resources to fill any gaps.

Often our clients retain key technical responsibilities for their products.

Our tools and processes are designed to be compatible with your needs so that technical and project-level communications are tight.

This generates decisions which are correct and timely, and ensures a successful project execution.

- Engineering Program Managers

- Responsible for customer and business relationship

- Single point of contact for customer

- Manage with a phase gate process

- Communications focal point

- Manufacturing Program Management:

This includes:

- Manage the project team to execute program tasks and own execution of supply chain deliverables --schedule, cost, quality, make / buy, supply chain complexity and lead time

- Develop and manage detailed Microsoft Project NPI trial run schedule with cross-functional team.

- Lead mitigation plan and recovery actions

- Management of ECN ( Engineering Change Management) implementation.

- Interpret and review engineering drawings, test plans, and technical specifications.

- Interface with Project Management Organization , Design, Manufacturing Engineering , Factory(s), NPI Sourcing, Supplier Development / Quality Engineering

- Ensure successful transfer of deliverables from Technology to Supply Chain and suppliers

- Lead Manufacturing Readiness Level assessment and transfer to production

Most product development projects include Hardware, Software and Mechanical Design elements. We will create a project plan specifically for your development project. With each engagement, no matter who is doing the design work, we can apply our DFX (DFM, DFT, DFQ, DFC) feedback into the design to ensure success at our customers facilities.